Our Services

Manufacture of all types of injection molding component and Auto spare components with competitive price

SR Engineering manufactures Automotive Plastic Injection Molding Components with many types and grades of plastic resins. We manufacture and exports the products which are world class quality,100% on time delivery and cost effective parts. Nowadays automotive industries are undergone various changes when it comes to designs and manufacturing techniques. Various assembled parts and other components are made from Automotive plastic parts manufacturer for better performance as well as to enhance durability. We are specialized in standard as well as custom-made components in automotive industry.

We have trusted and renowned name in the industry for quality Automotive Plastic Injection Molding Components. We understand thorough nature of the automotive industry. Hence, we manufacture highly precise and durable Plastic Components For Automobile Industry. We can also design, Manufacture and also deliver performance-oriented automotive injection molding solutions using various grades and types of plastics.

Role of Injection Molded Plastic Components in Automobiles

Interior parts assembly in Automobile engines requires thermoplastic components for best performance. Flexibility and adaptable nature of automotive plastic injection molded parts make them perfect for manufacturing parts or even complete devices for automotive industry.

Design and Development of Jig & Fixtures, Injection Mould and Tools

We Design and Develop Die Casting Dies, Die Tools, Moulds, Jig, Fixtures, Plastic Injection Moulds and Engineering Job Works.

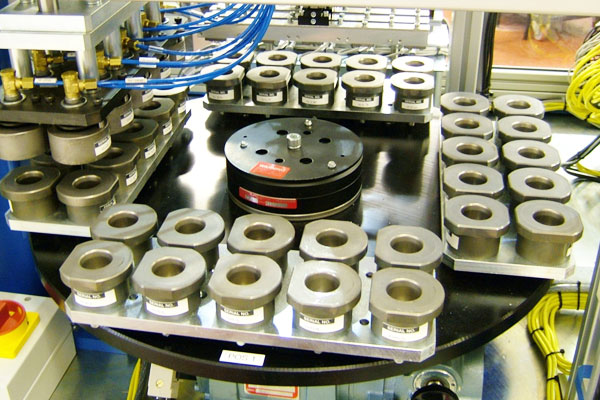

Jigs & Fixtures

Jigs & Fixtures offered are designed and manufactured in precision constructed finish and find application in meeting the demands of machining and inspection of different fix tools and components. With our expertise in offering these jigs and fixtures as per the specific design requirements and demands of the customers, we ensure these are made up of quality forging material in accordance with set industry standards. Further, these fixtures are used as permanent and complex holdings and are extensively demanded for undertaking defined industrial applications. We have promoted best quality Fixtures in the competitive market.

We provide our clients with welded fixtures which are very useful for handling the material which has complicated shapes. We offer a spectrum of welded fixtures that are fabricated using qualitative raw material procured from reliable vendor. Our products are reckoned for their efficient positioning and competence to clutch two parts together.

Design and development of manufacturing layout with lean principles

We design and develop the manufacturing layouts, products by applying the lean principles and concepts and with the help of lean concepts like value stream mapping, Design for six sigma, DFMEA we can reduce the waste and maximizing the values and quality. We also use GD&T ASME Y14.5m system for dimensioning the manufacturing layouts. Design for lean manufacturing is a process for applying lean concepts to the design phase of a system, such as a complex product or process. Design for lean manufacturing systematically widens the design equation to include all factors that will determine a product's success across its entire value stream and life-cycle. One goal is to reduce waste and maximize value, and other goals include improving the quality of the design and the reducing the time to achieve the final solution. Multiple viewpoints are considered in Design for lean manufacturing. These are called out as four value streams; customer, product design and test, production, and knowledge. Design for lean manufacturing helps a team “knit together” existing tools. For example, the following methods and business tools can be used by organizations within the design for lean manufacturing methodology: Value Stream Mapping, Design for Six Sigma, Visual Control, QFD, DFMA, and Taguchi methods.

Fabrication of work tables and Material handling Equipment’s

We are instrumental in manufacturing and supplying superior quality Material Handling Equipment that is designed at par with the set quality standards. This is developed using high grade raw material and latest technology by our experts at our well-equipped manufacturing unit. This equipment is meticulously tested on various quality parameters to ensure its durability and reliability. The offered equipment is broadly appreciated by our clients due to its durable finish standards, user friendliness and long lasting durability.

PLC Programming Services

A PROGRAMMABLE LOGIC CONTROLLER (PLC) is an industrial computer control system that continuously monitors the state of input devices and makes decisions based upon a custom program to control the state of output devices. The program defines the full operation of the machine, and a well-written program is critical to maintaining and extending the system to maximize its productive life and achieve full ROI.

We are providing PLC programming services to our customers.

The PLC programming services is done by experts with more than five years of control systems experience of various systems and industries. We provide programming services of various brands of PLC’s like Siemens, Allen Bradley, ABB,Omron, Schneider. Our controls and electrical engineers are trained on multiple platforms and develop programs in both state machine and step logic structures. Our team will understand your requirement and based on that we do programming, wiring, fitting and panel design.

Our Clients

Let's Get Your Project Started Today!

Feel free to contact us

S.R. Engineering Solutions started a small beginning in 2012 and our company has supplying finished products to various industries Automotive...Read more

Quick links

Get In Touch

- Address:

234, CNS Street, Newtown, Vaniyambadi, Vellore District, Pincode - 635751 - Phone: + 91 8939079631

- Email: sales@srengsolutions.com